ELASTIC / RUBBER COVERING

KEY FEATURES :-

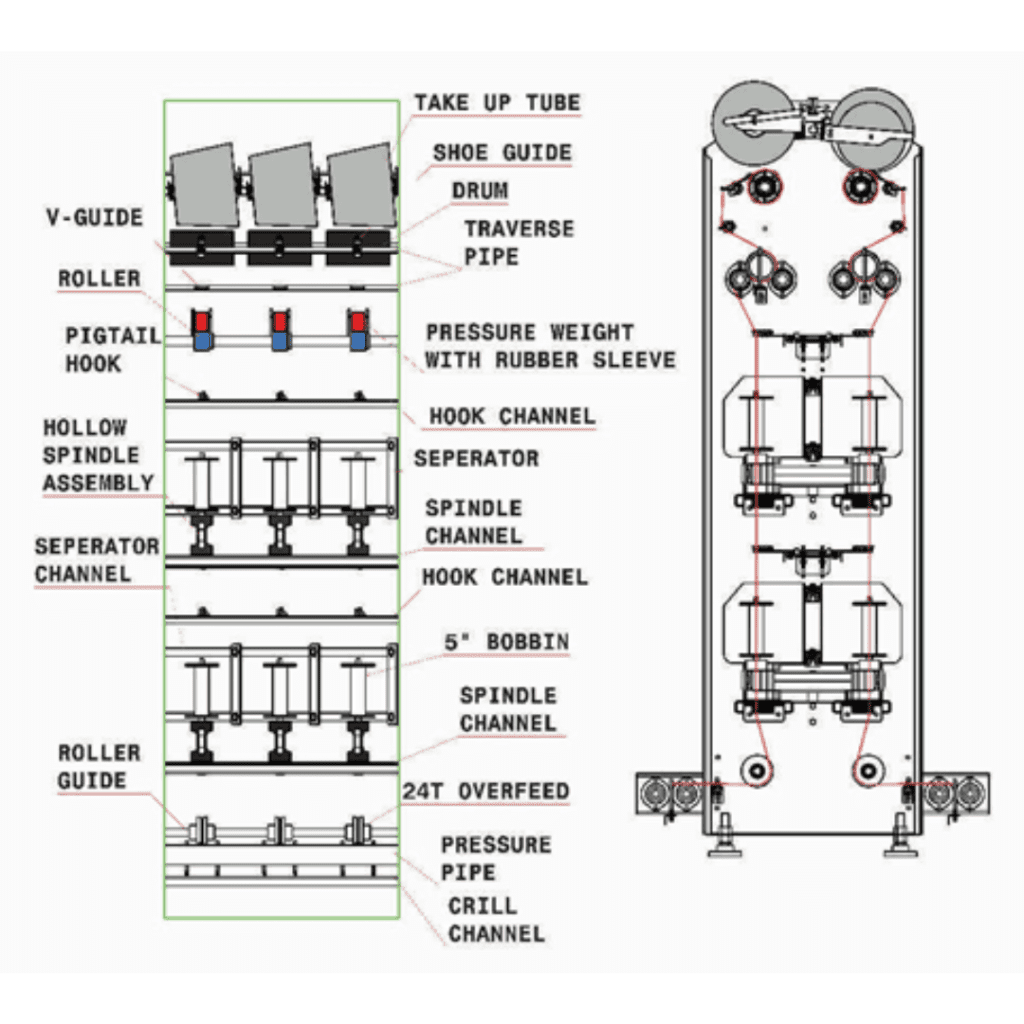

- Modular sheet metal structure to deliver strong mechanical support and sturdiness and stability at higher speeds.

- Yarn feed control setting providing with overfeed settings

- Tpm and rpm automation for easy operation without any need to change any gear and pulleys.

- Pressure roll covered with rubber sleeve to ensure to finest quality delivered from the machines

- Special gun drilled one piece hollow spindle to increase life and ensure the uniform quality of yarn produced.

- High temperature greasing bearing to maintain the performance of the bearings and spindle and their life.

- Superior quality with good stretch and covering of effect yarn. Smooth finishing of final product produced as per requirement.

- High speed spindle machine designed to make the conversion cost economical.

- Low electricity consumption, helps you fulfill the responsibility of energy conservation & also benefits in reduced production cost.

- Optional direct beam take up attachment provision.

- Cast iron bearing pedestal to increase life and reduce frequent maintenance.

- 7 tank powder coated process machine structure ensure long life & performance of machine.

National Elastic yarn covering machine or rubber yarn covering machine, widely used for manufacturing yarns for making elastic tapes, face mask elastic, elastic string, garment elastic accessories, garment smoking, used in production for undergarments, socks panty hose, etc

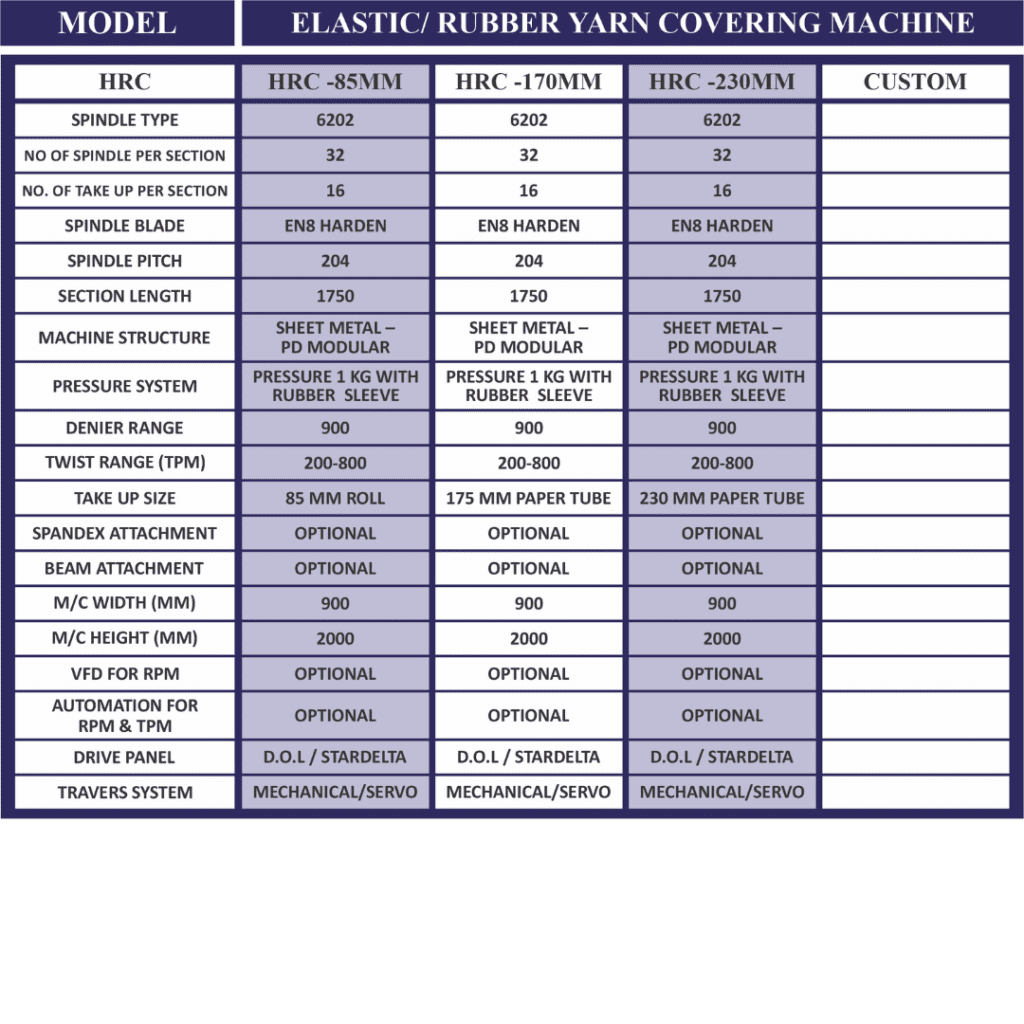

elastic / rubber yarn covering TECHNICAL SPECIFICATIONS:-

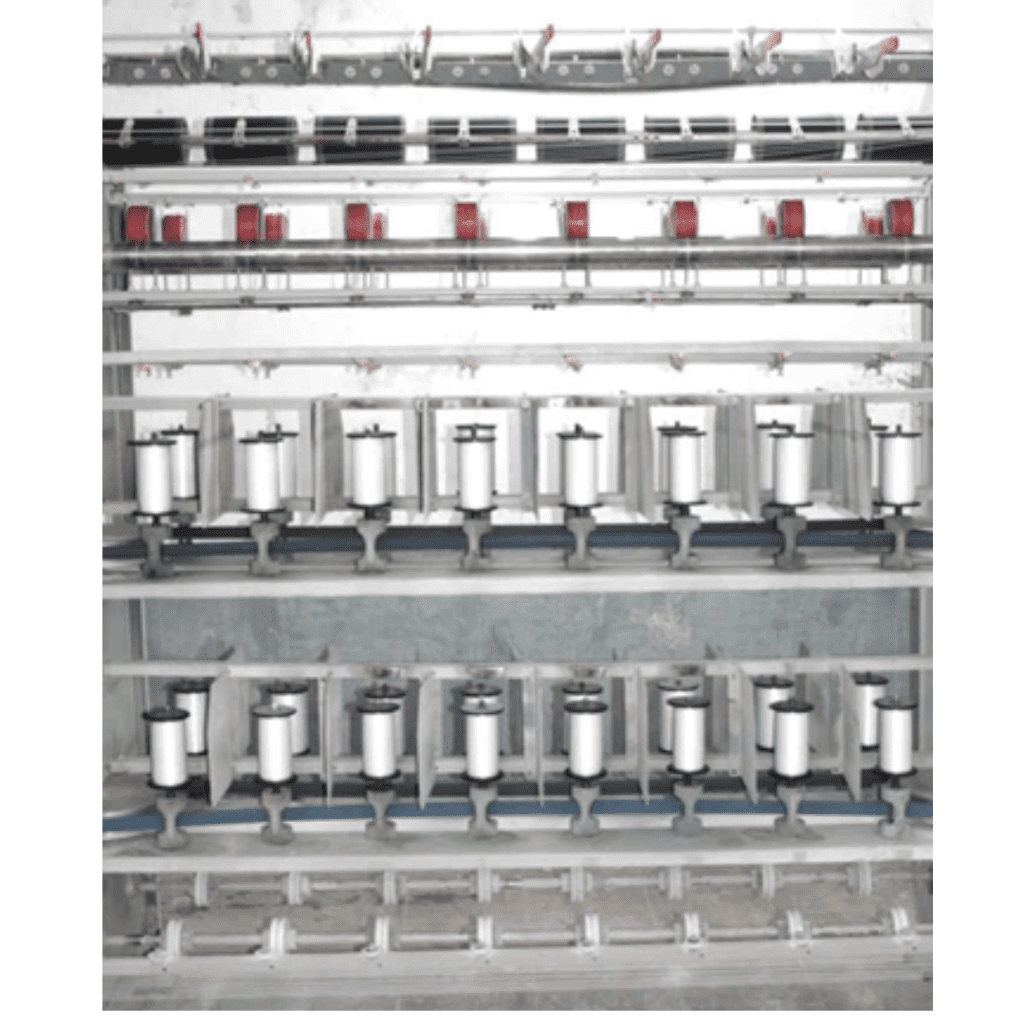

SPINDLE

Specially gun drilled one piece hollow spindle with optimum pulley size to reduce energy consumption and maximize the spindle rpm to ensure higher production rates. Enclosed in housing and mounted with High temperature greasing bearing to ensure performance at higher speeds

GEARBOX / CAMBOX

Auto oil circulation gearbox box with dedicated motor and pump to ensure continuous lubrication And minimize wear and tear maintenance. Fully oil immersed cambox to reduce mechanical friction, efforts and losses

+ Easy operating of gearbox with 6-8 gears covers a wide

range of 100-3000 tpm in just 10 min.

+ Fully manufactured In house to ensure the life long quality performance.

+ Anti patterning settings for take up package winding

PACKAGE SIZE

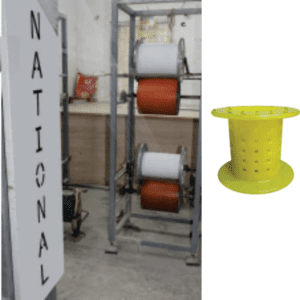

Wide range option to choose from roll takeupsize , direct papertubetakeup sizes , or direct beam takeup also available with attachment to takeupupto 3 beam at a time. Depending upon the end use of yarn take up package size can be customized and opted accordingly.

PLC CONTROL SYSTEM

Plc system with touch screen HMI display to access and control machine working parameters effortlessly just with control of simple touch. Servo motor and servo systems ensures precise and steeples setting of all parameters.

+ RPM control for changing rpm for different yarn count.

+ TPM control to set and change different tpm.

+ TRAVERS Control to control cross winding angle on takeup package

SPANDEX ATTACHEMENT

This machine can be geared up with spandex attachment which will enable and makes the machine flexible to run spandex/lycra yarn as well and elastic yarn as well on same machine at a time. This allows customer to cater requirements from a wide market segment.

ANYTHING ELSE YOU WANT TO ACCOMPLISH WITH SPANDEX YARN COVERING MACHINE/ LYCRA YARN COVERING MACHINE..? ENTHUSIAST FOR DEVELOPING NEW PRODUCTS AND INFLUENCE THE MARKET ..? DROP US AN INQUIRY WOULD LOVE TO CRAFT A UNIQUE SOLUTION ACCORDING TO THE REQUIREMENT.