COTTON / SPUN TFO [DOUBLE DECK]

SPUN TFO DOUBLE DECK KEY FEATURES :-

- Modular sheet metal structure to deliver strong mechanical support and sturdiness and stability at higher speeds.

- Yarn path is designed in a such way that it ensures minimum tension on yarn and reduce electricity consumption, which is been achieved by quality designed of machines.

- Ceramic devices and hard anodized/plasma coated spindles for handling the filament yarn delicately to ensure optimum quality.

- Complete oil immersed cambox for trouble free smooth operation and minimum wear & tear through the 20 years of life of machine.

- Auto oil circulation gearbox take cares of its own lubrication, without any regular attention of operator. Which reduces maintenance cost of machines.

- Long yarn path design for proper twist setting and control of quality.

- Overfeed system to control package density and optimize for making soft package ready for dyeing.

- Dynamically balanced precession spindles and imported nylon double sandwiched belt improves performance and reduce mechanical losses.

- Extremely lower production cost due to machine design, lower electricity consumption higher spindle speed. Which improves production with context to time.

National SPUN TFO machine is the most Efficient choice, in terms of production cost, for producing 2ply-3ply & multiply doubling twisting of yarn like Spun yarns, Cotton Yarns , PC , PSF . PV , we have twisting solutions from (90MM — 310MM) spindle size and for almost any industry you can come up with.

With our infrastructure, strong team of qualified engineers, and profound knowledge and understanding of textile industry we are specialized in customization, According to customers, custom requirements.

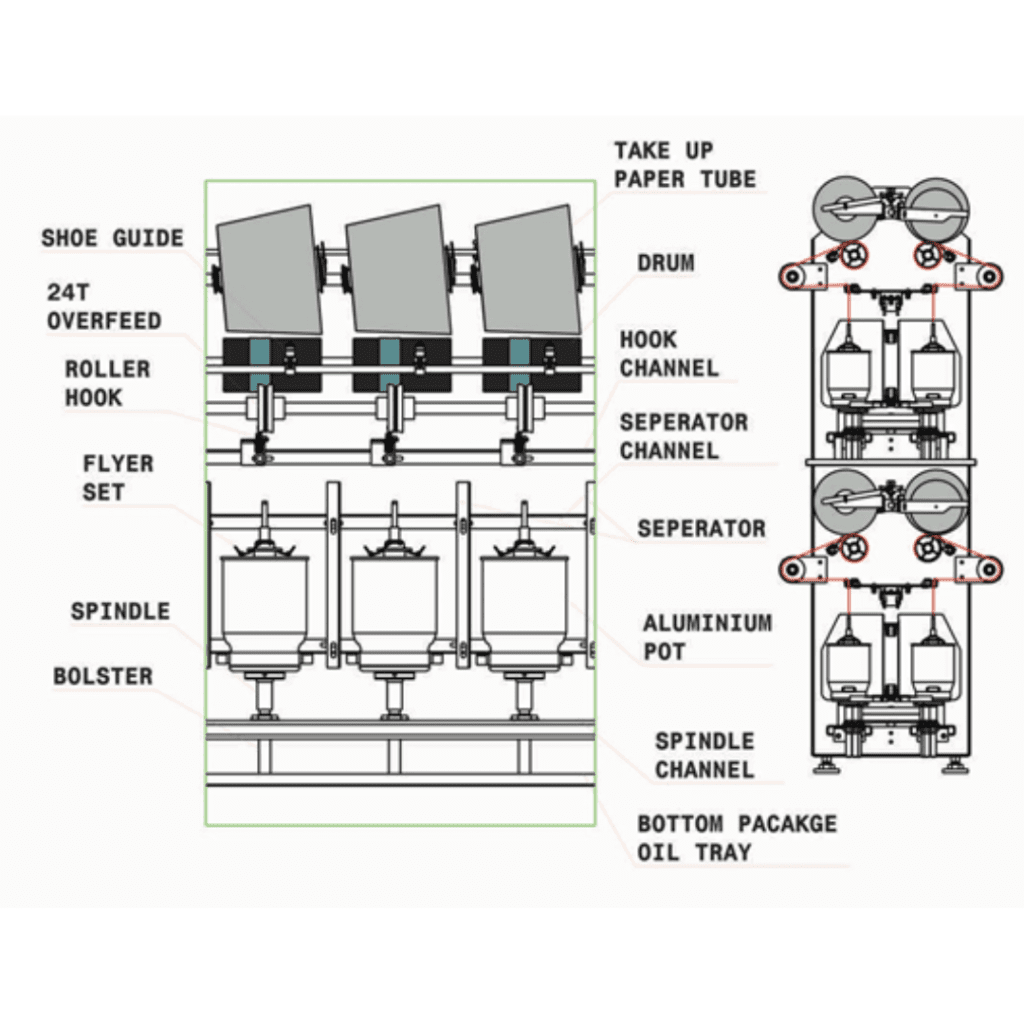

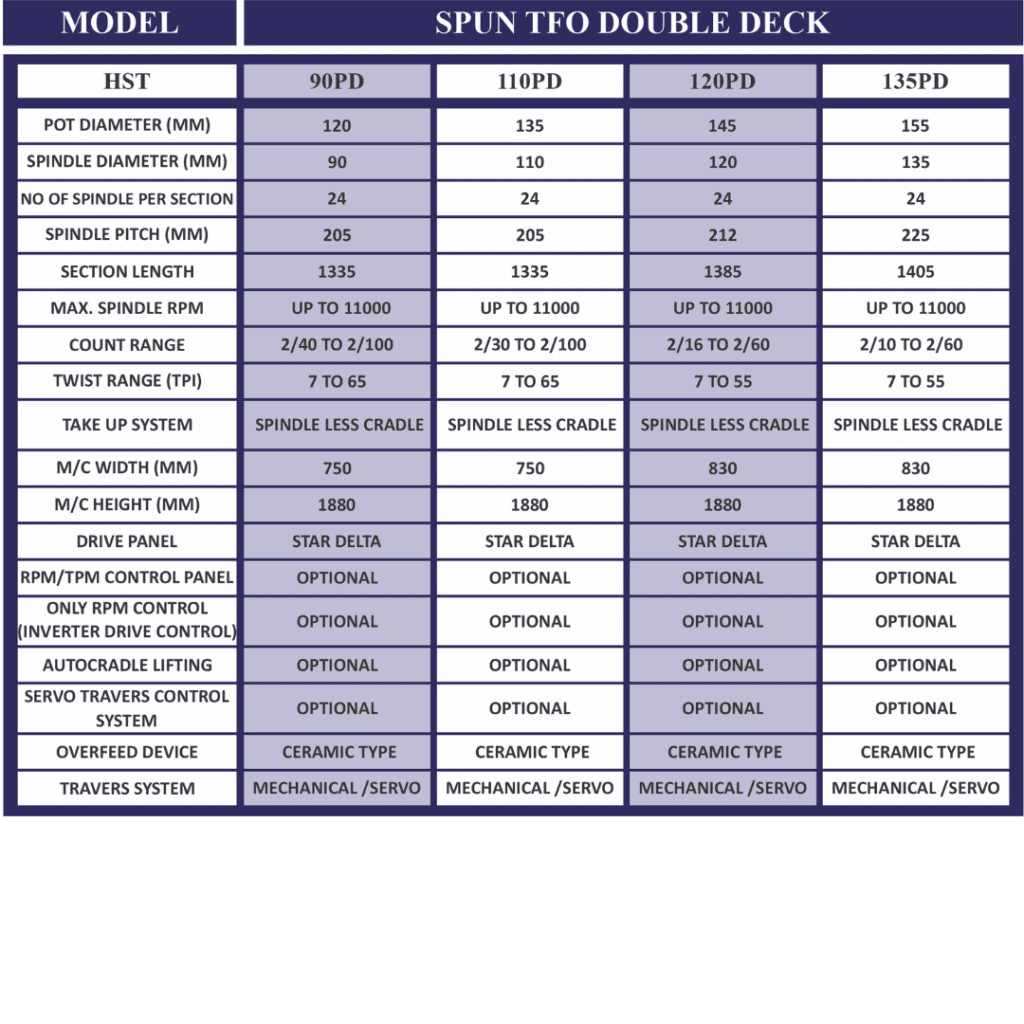

SPUN TFO dOUBLE dECK TECHNICAL SPECIFICATIONS:-

SPINDLE

The spindles are dynamically designed by keeping energy conservation in mind and optimum reserve area the place where twist are set on yarns which ensure the quality. Spindle are optimized to maximize feed package weight without increasing energy cost.

- Energy efficient spindles design

- Maximum reserve area for Yarn twist quality

- Optimized to maximize feed package for better efficiency

GEARBOX / CAMBOX

Auto oil circulation gearbox box with dedicated motor and pump to ensure continuous lubrication And minimize wear and tear maintenance. Fully oil immersed cambox to reduce mechanical friction, efforts and losses

+ Easy operating of gearbox with 6-8 gears covers a wide range of 100-3000 tpm in just 10 min.

+ Fully manufactured In house to ensure the life long quality performance.

+ Simple cambox setting to alter traversing and length.

+ Anti patterning settings for take up package winding

PACKAGE SIZE

Wide range option to choose from roll takeup size , direct papertube take up sizes. Depending upon the end use of yarn take up package size can be customized and opted accordingly.

PLC CONTROL SYSTEM

Plc system with touch screen HMI display to access and control machine working parameters effortlessly just with control of simple touch. Servo motor and servo systems ensures precise and steeples setting of all parameters.

+ RPM control for changing rpm for different yarn count.

+ TPM control to set and change different tpm.

+ TRAVERS Control to control cross winding angle on takeup package

IF YOU ARE LOOKING TO COMPETE EMSTING TEXTILE INDUSTRY WITH PRODUCTION, QUALITY AND VIABILITY NATIONAL TFO IS RIGHT CHOICE FOR YOU. CAN EASILY GIVE YOU COMMAND OVER COMMERCIAL AS WELL AS TECHNICAL ASPECT OF TEXTILE INDUSTRY.