High-Quality Filament TFO (Paper Tube Take Up) Machines

Explore our cutting-edge Filament TFO machine, a pinnacle of filament twisting technology that sets new benchmarks in yarn production. With our integrated paper tube take-up mechanism, experience seamless operation and heightened efficiency, leading to superior yarn twisting efficiency.

Elevate your textile production with our high-quality yarn twisting solutions. Our yarn twisting equipment stands as a testament to our commitment to excellence. We offer more than just machinery; we provide yarn production solutions tailored to your unique needs.

Our range of advanced textile machinery incorporates the latest textile production technology to ensure precision at every step. Witness the future of yarn creation through our TFO yarn twisting process, designed to optimize the yarn twisting process while maintaining the utmost quality.

At National Textile Engineering Industries, innovation is our hallmark. Our yarn twisting innovation drives our passion for excellence, resulting in top-tier textile machinery that caters to your evolving demands. Step into the world of filament yarn production with us and experience the art of textile engineering.

Experience efficiency like never before with our efficient yarn twisting solutions. From the heart of our machinery to the core of your operations, we’re committed to enhancing your productivity. Our paper tube winding technology streamlines your workflow, reducing downtime and maximizing output.

Uncover the potential of your textile endeavors with National Textile Engineering Industries. Contact us today to explore our range of textile production technology, embracing the future of yarn production. With our unwavering dedication, we’re here to transform your visions into reality.

FILAMENT TFO KEY FEATURES :-

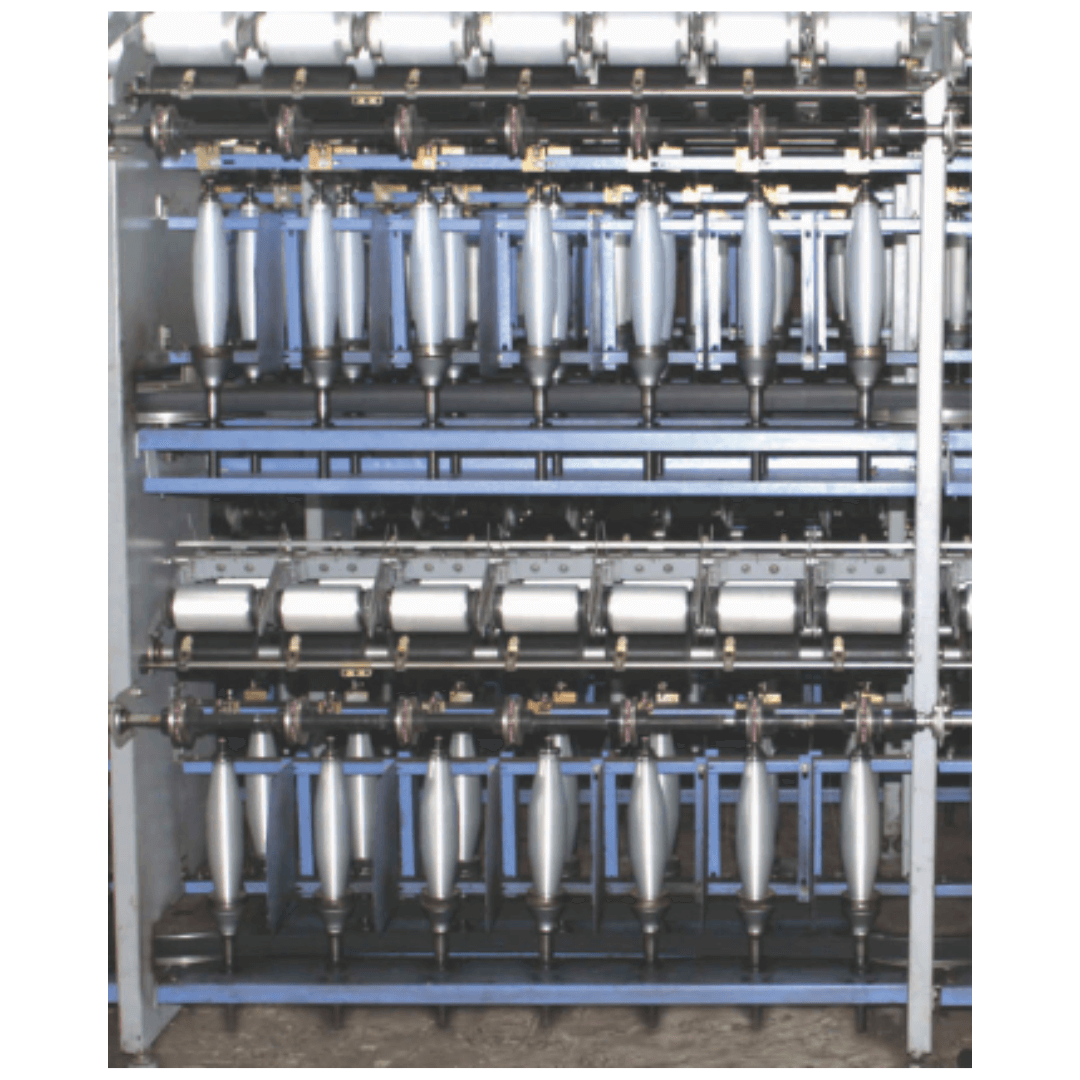

- Modular sheet metal structure to deliver strong mechanical support and sturdiness and stability at higher speeds.

- Yarn path is designed in a such way that it ensures minimum tension on yarn and reduce electricity consumption, which is been achieved by quality designed of machine

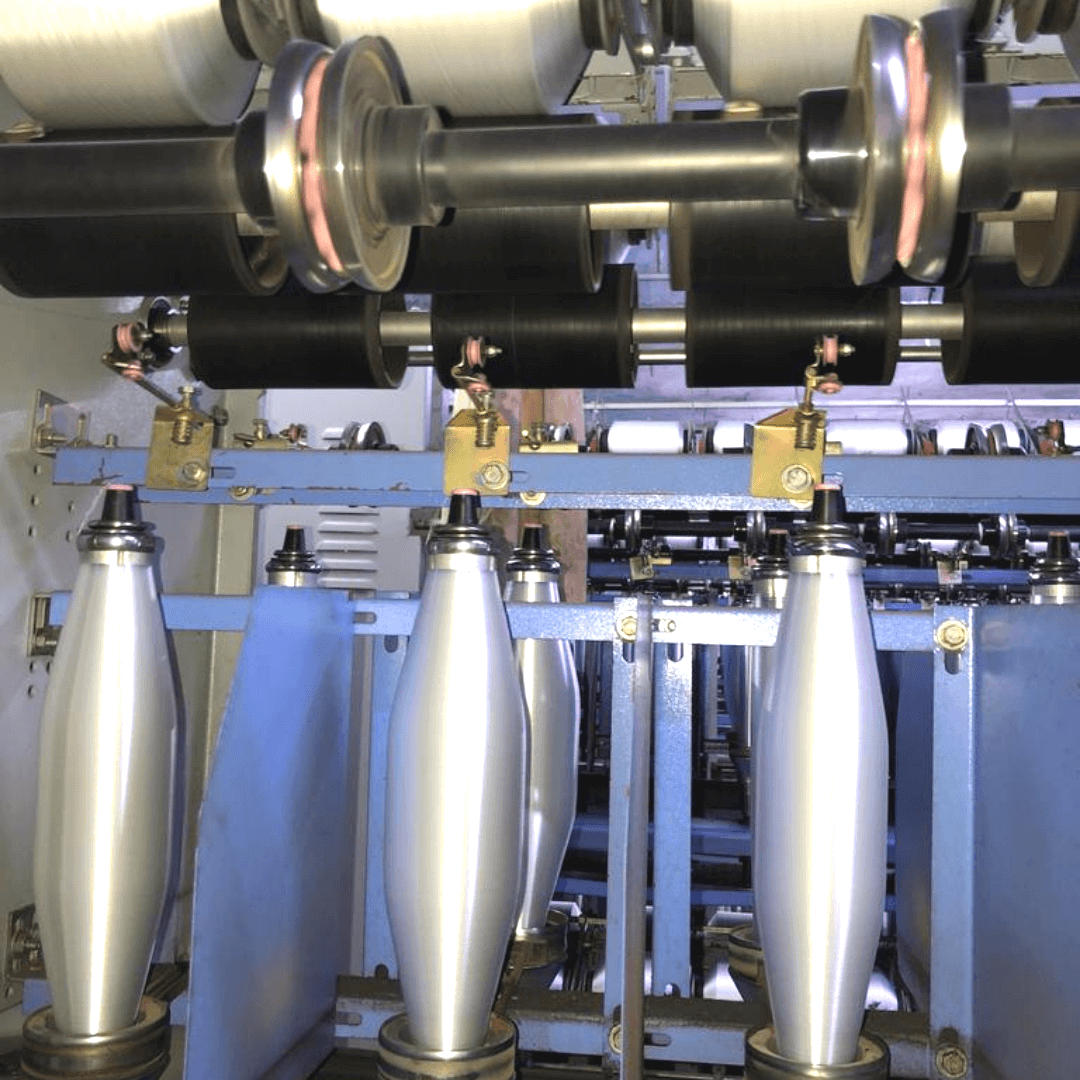

- Ceramic devices and hard anodized/plasma coated spindles for handling the filament yarn delicately to ensure optimum quality.

- Complete oil immersed cambox for trouble free smooth operation and minimum wear & tear through the 20 years of life of machine.

- Auto oil circulation gearbox take cares of its own lubrication, without any regular attention of Which reduces maintenance cost of machines.

- Long yarn path design for proper twist setting and control of quality.

- Overfeed system to control package density and optimize for making soft package ready for Dyeing.

- Dynamically balanced precession spindles and imported nylon double sandwiched belt improves performance and reduce mechanical losses.

- Extremely lower production cost due to machine design, lower electricity consumption higher spindle Which improves production with context to time.

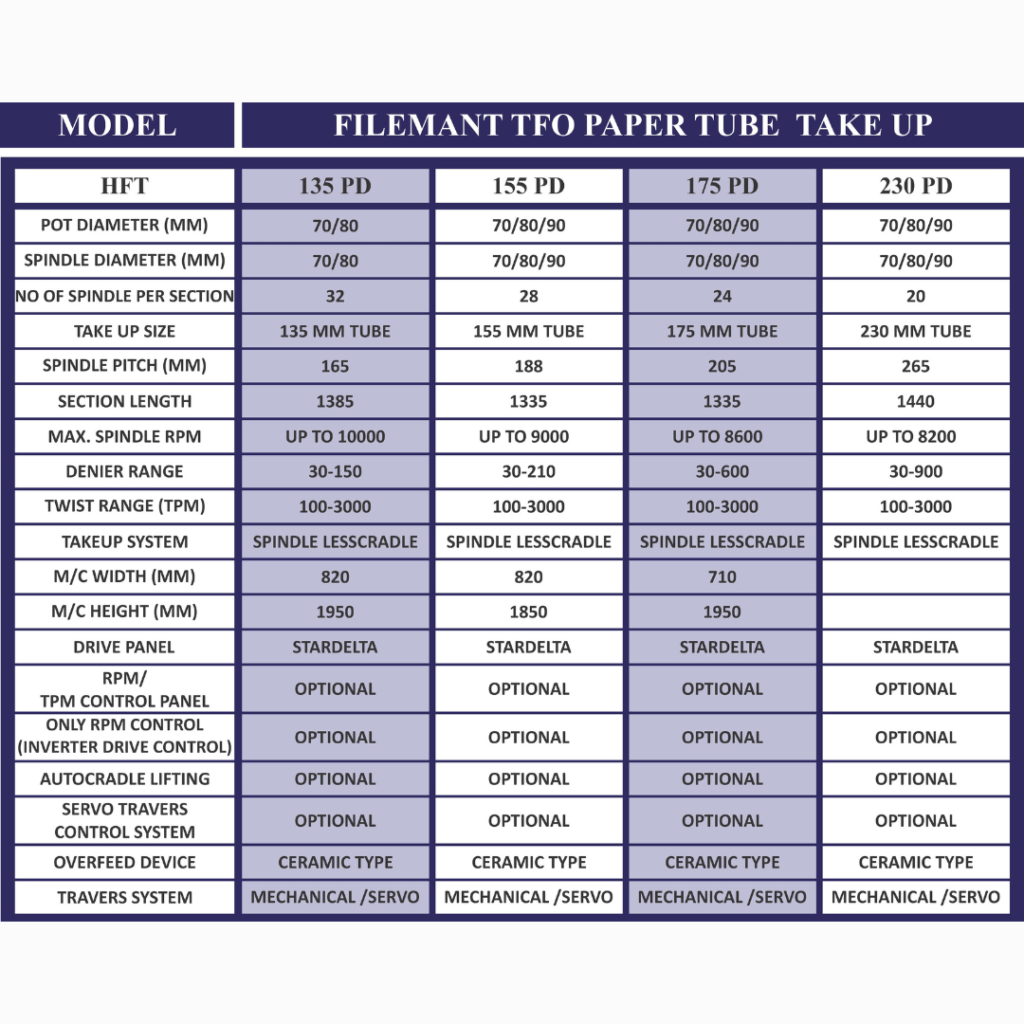

National filament tfo machine are most reliable as well as economical solution for textile industry where fine deniers of yarn have to imparted with high twist for manufacturing fabrics used in sarees, dress material, pocketing fabrics, liners etc. For high twist yarn heat setting is critical to make it use in process of weaving or knitting depending on user preferences. We have multiple options for take ups from (100MM — 135MM) Roll size and (135MM — 230MM) papertube size With wide range of spindle selection size from (60MM — 310MM) and as suitable with customer requirements.

FILAMENT TFO TECHNICAL SPECIFICATIONS:-

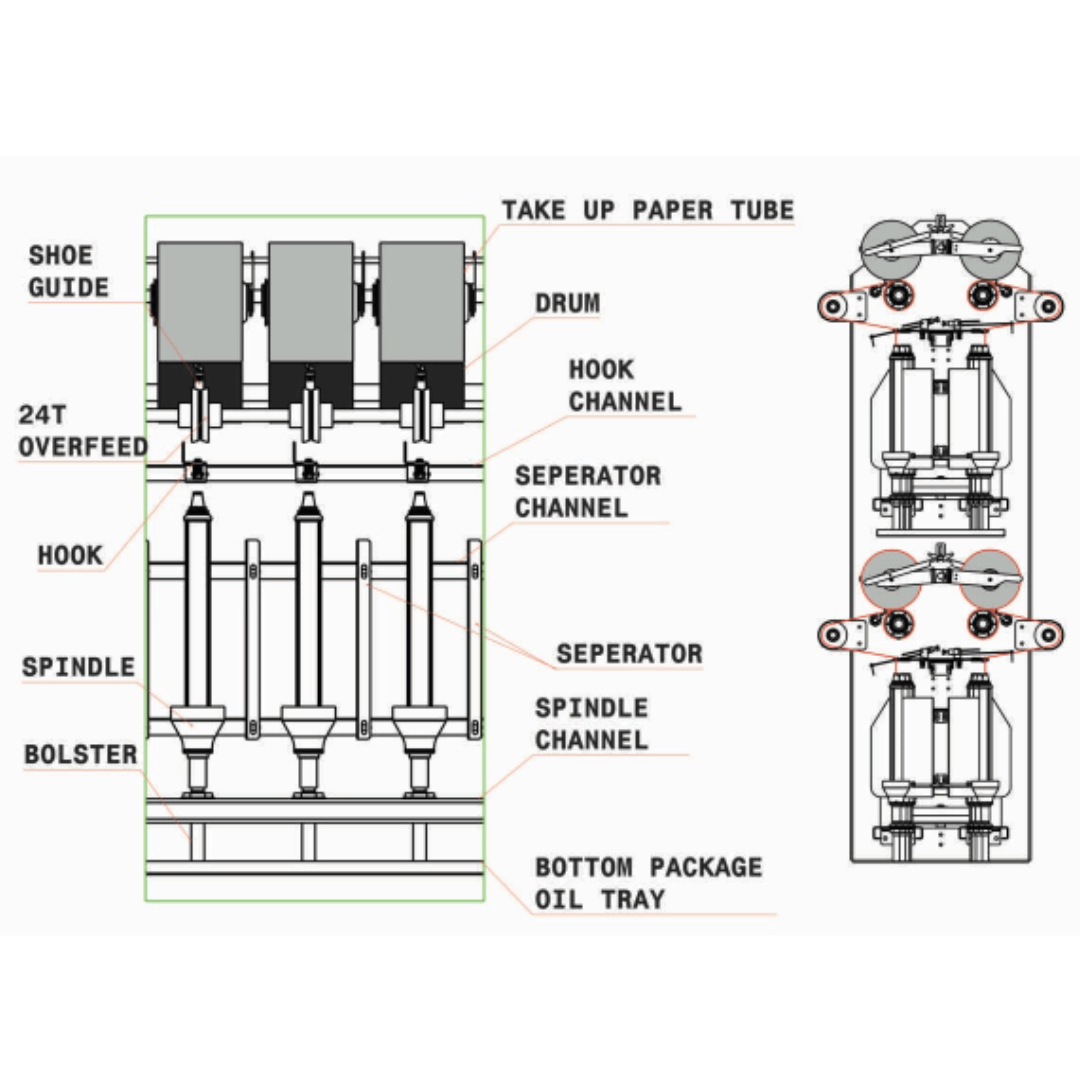

SPINDLE

Dynamically balanced designed spindle available in S.S , HARD ANODISED AND PLASMA COATING

Allows us to cater a wide range of requirement from the market. Proper size and type of spindle selection is necessary to process different types of yarn & feed packages.

+ Energy efficient design spindles

+ Wide range for spindle type & size selection

GEARBOX / CAMBOX

Auto oil circulation gearbox box with dedicated motor and pump to ensure continuous lubrication And minimize wear and tear maintenance. Fully oil immersed cambox to reduce mechanical friction, efforts and losses

+ Easy operating of gearbox with 6-8 gears covers a wide range of 100-3000 tpm in just 10 min.

+ Fully manufactured In house to ensure the life long quality performance.

+ Simple cambox setting to alter traversing and length.

+ Anti patterning settings for take up package winding

PACKAGE

Wide range of take up option available in papertube takeupfrom l35mm to 230mm papertubesize for final package.Direct Soft package – a special combination of gears enables soft package winding directly from the machine with edge breaking mechanism , so package can be taken for dyeing eliminating in between process. Proper selection to be done on the basis of application in industry, type of weaving machine & its speed to ensure maximum working efficiency

PLC CONTROL SYSTEM

Plc system with touch screen HMI display to access and control machine working parameters effortlessly just with control of simple touch. Servo motor and servo systems ensures precise and steeples setting of all parameters.

+ RPM control for changing rpm for different yarn count.

+ TPM control to set and change different tpm.

+ TRAVERS Control to control cross winding angle on takeup package

If you are looking to compete existing textile industry with production, quality and viability NATIONAL TFO is right choice for you. can easly give you command over commercial as well as tehnical aspect of TEXTILE INDUSTRY.