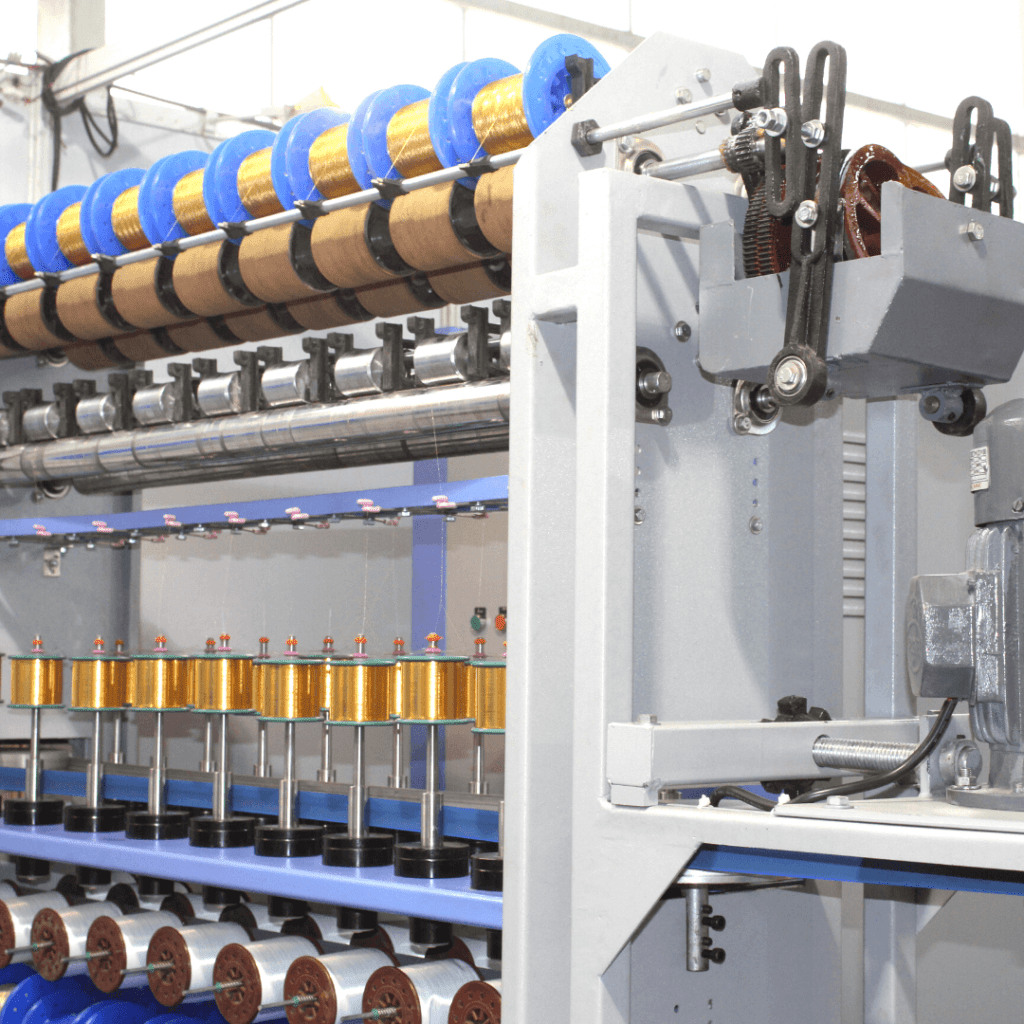

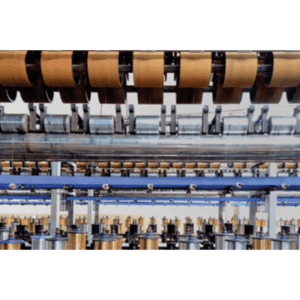

JARI COVERING [ROLL TAKE UP]

HOLLOW JARI COVERING MACHINE KEY FEATURES :-

- Special gun drilled one piece hollow spindle to increase life and ensure the fine quality of jari yarn produced

- High temperature greasing bearing to maintain the performance of the bearings and spindle and their life.

- Modular sheet metal structure to deliver strong mechanical support and sturdiness and stability at higher speeds.

- Superior shining jari production without flaws, twist variation and shade variation.

- High speed spindle machine designed to make the conversion cost economical.

- Low electricity consumption, helps you fulfill the responsibility of energy conservation & also benefits in reduced production cost.

- Cast iron bearing pedestal to increase life and reduce frequent maintenance.

- 7 tank powder coated process machine structure ensure long life &performance of machine.

National Jari covering machine.If looking or planning for jari covering machine, national brand jari covering machines is most reliable option for you because of rich industry experience not in just manufacturing machine but also in quality produced of final jari. With hand holding supports throughout the journey we are with you ti11 the you are satisfied with the finaI quality produced from machine .

In terms geography surat is world largest manufacturer for jari, and where in if we talk about big players in industry we are the prominent supplier for jari covering machine.

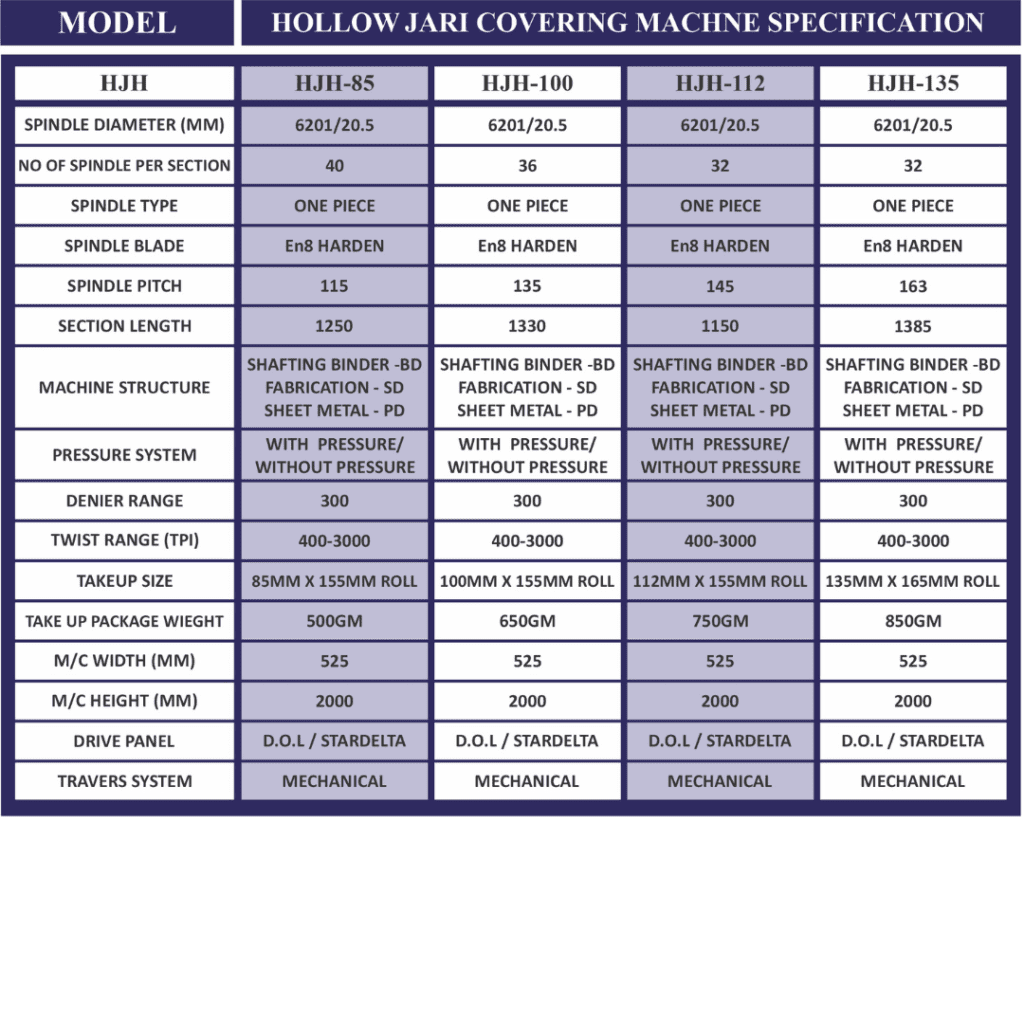

hollow jari covering machine TECHNICAL SPECIFICATIONS:-

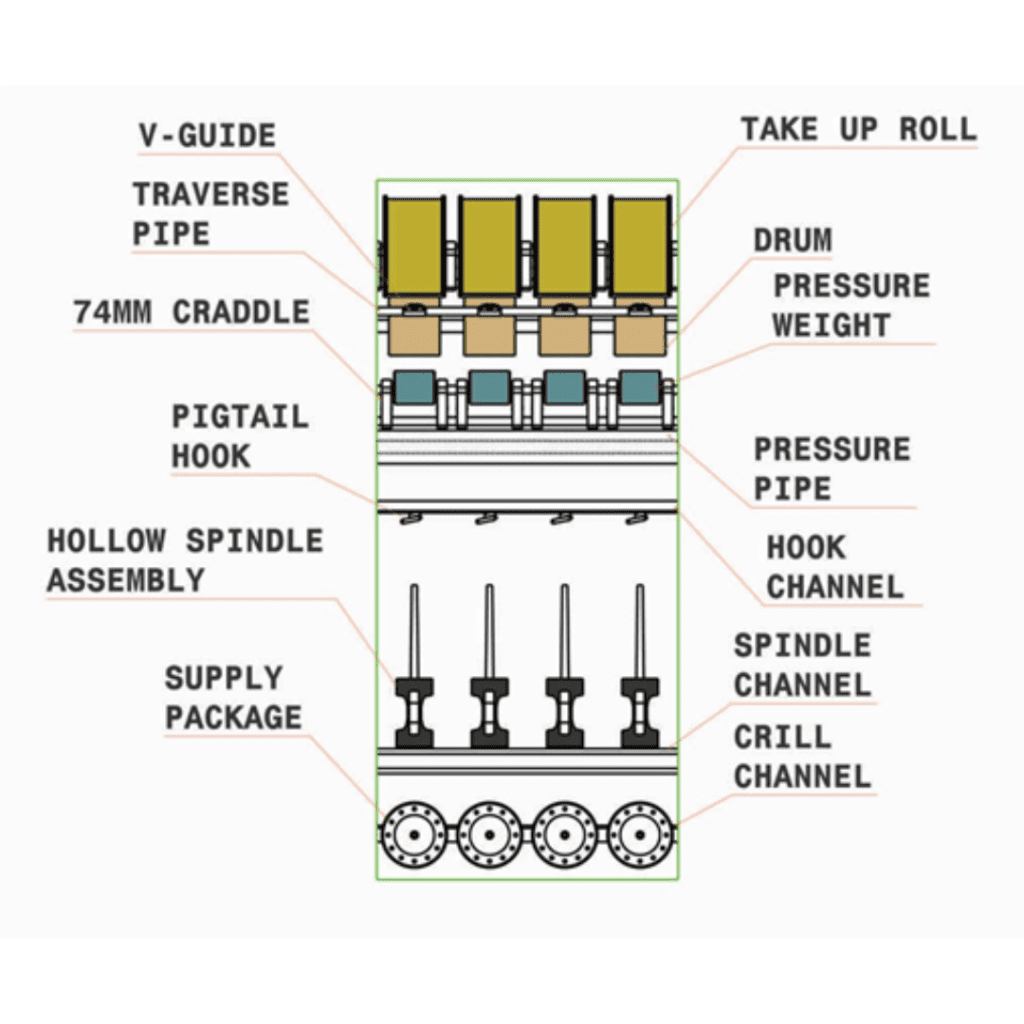

SPINDLE

Specially gun drilled one piece hollow spindle with optimum pulley size to reduce energy consumption and maximize the spindle rpm to ensure higher production rates. Enclosed in housing and mounted with High temperature greasing bearing to ensure performance at higher speeds

GEARBOX / CAMBOX

- Auto oi1 circulation gearbox box with dedicated motor and pump to ensure continuous lubrication And minimize wear and tear maintenance. Fully oil immersed

cambox to reduce mechanical friction, efforts and losses

+ Easy operating of gearbox with 6-8 gears covers a wide range of 100-3000 tpm in just 10 min.

+ Fully manufactured In house to ensure the life long quality performance.

+ Anti patterning settings for take up package winding

PACKAGE SIZE

Range of option available for selection of package size required from 350gm —lkg required for different market segment from embroidery to narrow fabric to weaving industry

PRESSURE SYSTEM

SS Pipe known superior surface finish and longer life with pressure weights with hard chrome coating arrangement deliver the perfect pressure needed on jari after metallic is covered to get the smooth finishing and shining yarn quality

ALONG WITH MACHINE QUALITY AND FINAL PRODUCT QUALITY, YOU ALSO GET ACCESS TO OUR HANDHOLDING SUPPORT. AND INDUSTRY RICH EXPERIENCE & GUIDANCE FOR LIFETIME.